A Maintenance Guide to Improve Mold Performance

1. Identifying Guide Pillar Wear Issues

Typical Symptoms

Difficulty in mold opening/closing requiring increased clamping force

Inconsistent part dimensions within same production cycle

Abnormal noises (squeaking/grinding sounds during operation)

Visible scoring marks along pillar surface upon inspection

Consequences of Neglect

→ Permanent loss of mold precision

→ Damage to guide bushings (higher repair costs)

→ Increased part rejection rate

2. Root Cause Analysis

2.1 Material Limitation

Low-carbon steel pillars: Soft surface (HRC20-30) prone to scoring

Poor surface finish: Rough texture accelerates wear

Solution: Upgrade to hardened materials (chrome-plated/SUJ2 bearing steel)

2.2 Lubrication Issues

Dried lubricant: Infrequent regreasing

Contaminated grease: Mixed with plastic/metal particles

Improper grease type: Standard grease unsuitable for high temps

Solution: Implement scheduled lubrication with high-temp grease

2.3 Alignment Problems

Misalignment: Eccentric movement causes uneven wear

Improper clearance: Too tight increases friction, too loose causes impact

Solution: Use dial indicators for precision installation

3. Practical Solutions

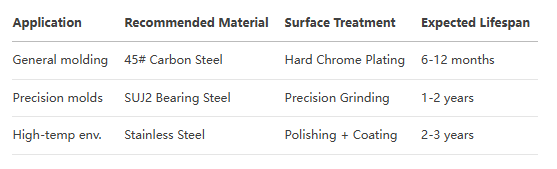

3.1 Material Selection Guide

3.2 Lubrication Protocol

Cleaning: Use kerosene + lint-free wipes

Grease Selection:

Normal temp: Lithium-based grease (NLGI 2)

High temp (>80°C): Molybdenum disulfide grease

Frequency:

Continuous production: Replenish every 3 days

Intermittent use: Weekly inspection

3.3 Maintenance Checklist

Monthly:

Measure diameter change (replace if wear >0.02mm)

Inspect bushing inner surface

Annual:

Complete disassembly for polishing

Replace wear-resistant bushings

4. Pro Tips

4.1 Quick Alignment Check

Rotate pillar 360° while measuring clearance with feeler gauges (max variance <0.01mm)

4.2 Emergency Repair

Minor scoring can be hand-polished using oilstone + diamond paste

4.3 Storage Advice

For long-term storage:

Apply rust preventive oil

Cover with protective film

5. FAQ

Q: Do guide pillars require scheduled replacement?

A: Quality pillars last 2-3 years with proper maintenance. Replace immediately if:

Deep grooves (>0.05mm) appear

Diameter reduction exceeds 1%

Visible bending deformation

Q: Can we mix pillars from different manufacturers?

A: Not recommended. Dimensional tolerances vary between brands.

Q: Is thicker grease better?

A: No. Follow viscosity guidelines:

Slow/heavy loads: NLGI 2

Fast/light loads: NLGI 1

6. Conclusion

Though small, guide pillars function as the mold's "joints." Implement:

✓ Proper material selection

✓ Systematic lubrication

✓ Regular alignment checks

Have specific guide pillar challenges? Share your experience below!