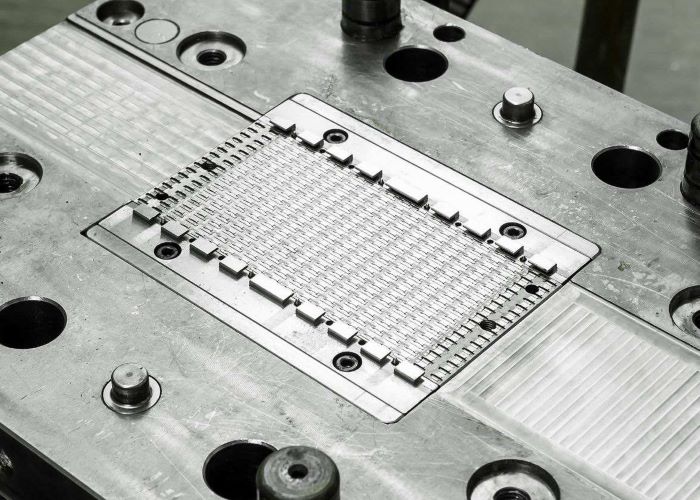

In the precision mold manufacturing process, strict control of process parameters at each stage is essential to ensure mold accuracy. Taking the production of two-part rubber oil seal molds as an example, the core process flow includes mold cleaning, semi-finished product placement, mold closing for vulcanization, and product ejection. The molds are manufactured by processing individual components before assembly, with the mold cavity made of Cr12 steel and the connecting plates using 45# steel. Beyond strict adherence to design drawings, special attention must be paid to the following four critical precision control points:

First is the optimization of glue flow channel processing. Traditional methods often resulted in channels being too far from the cavity or with uncontrolled dimensions, causing trimming difficulties. The improved triangular channel adopts a "zero-to-zero" design where the inner dimension matches the product's outer diameter exactly. The sharp edges formed by the upper and lower molds automatically shear excess flash. This breakthrough simplifies trimming by approximately 40% and increases product appearance qualification rate to 99.5%.

Second is the innovative taper fit between the upper mold and core. Traditional hand-scraping required over 80% contact area yet still couldn't eliminate flash. The new solution uses a slightly smaller taper angle in the female part combined with 5-axis machining, maintaining zero clearance at the parting line. Testing shows this improves fit accuracy to 0.005mm while completely eliminating flash and reducing assembly time by 60%.

Third is the upgraded core pressing process. For auxiliary lip dimensional accuracy, thermal expansion interference fit is employed, controlling machining errors within ±0.01mm, supplemented by preload screws. Practical results demonstrate 90% reduction in core displacement with significantly improved dimensional stability.

Finally, optimized floating connections between cavities. By precisely controlling the 0.5-1.0mm clearance between individual cavities and connecting plates, and implementing self-lubricating guide mechanisms, traditional issues of mold tilting and jamming are resolved. After 20,000 open-close tests, wear is reduced by 70% with 3x lifespan extension.

XP Mold's technological innovations have successfully transformed three-part molds into two-part configurations while maintaining product precision. This achieves