Thermal Runner Leakage Solutions by XP Mold

Common Leakage Symptoms

Nozzle seepage: Cured plastic buildup around tips

Parting line flashes: Excess material on product edges

Temperature instability: Erratic heater zone readings

Pressure drops: Requiring higher injection force

XP Mold's Analysis

1. Seal Failure

O-ring degradation: XP's high-temp Viton® seals withstand 300°C+

Thread loosening: Our copper-alloy nozzles minimize thermal expansion gaps

2. Structural Issues

Manifold warping: XP's titanium-stabilized plates maintain ≤0.01mm flatness

Poor machining: All XP components achieve Ra≤0.2μm surface finish

3. Operational Errors

Overheating: Follow XP's material-specific temp profiles

Contamination: Use XP-C3 cleaning pellets monthly

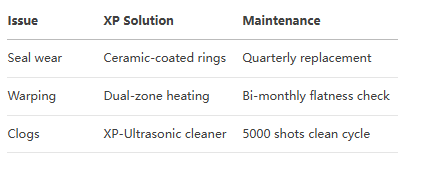

Tiered Solutions

🚨 Emergency Response

Safety shutdown: Keep mold closed

Cool & clean:

Reduce to 200°C

Use XP-T100 brass scraper kit

Temporary fix: Apply XP-Seal8 high-temp paste

🔧 Prevention Plan

XP Maintenance Protocol

✅ Installation:

Apply XP-Grease700 on seals

Torque nozzles to 25Nm (XP torque wrench included)

✅ Temperature:

Ramp-up 20°C/hour for new molds

±3°C stability with XP-PID controllers

✅ Daily Checks:

✔ Nozzle tip cleanliness

✔ Heater resistance values

✔ Pressure curve consistency

Why Choose XP Mold?

✓ Proven designs: 15+ years in thermal systems

✓ Quick support: 24/7 technical hotline

✓ Custom solutions: Send your mold data for tailored recommendations

"Precision doesn't happen by accident – it's engineered by XP."