In mold manufacturing, “high precision” is one of those terms people throw around a lot, but on the shop floor, it can mean very different things. From my years working with connector molds and optical parts, high precision isn’t just a number on a drawing—it’s about how a mold behaves during repeated runs and how much adjustment it requires during trial fitting.

I remember one project where a standard insert looked fine on paper. The first few shots were okay, but by the third batch, tiny misalignments caused flash along the edges. We swapped in a precision insert, and suddenly the problem disappeared. That’s when it really clicked for me: it’s not about perfection on paper, it’s about stability in production.

For a detailed comparison, see Precision Inserts vs Standard Inserts

.

Tolerance is often misunderstood. Some engineers think tighter always equals better, but in reality, tolerances need to match the application.

For example, we once tried ±0.002 mm on a non-critical positioning feature. The machining cost skyrocketed, and the part didn’t perform noticeably better. On the other hand, critical reference surfaces need ±0.005 mm or tighter. The difference is consistency, not just the number.

We like to think of it as fitting puzzle pieces. If the edges are too loose, the mold shifts. Too tight, and you struggle during assembly. Either way, it costs time and can introduce stress that shortens tool life. Getting tolerances right—where it actually matters—is the trick.

Surface finish is often underestimated. A polished surface doesn’t just look nice; it affects how inserts slide into place, how load spreads, and how wear occurs over time.

In practice, we focus on functional surfaces: sealing areas, contact faces, and visible product surfaces. Internal areas that don’t touch the plastic or other inserts don’t need extreme polish. I’ve seen cases where a mirror finish was done everywhere, but it didn’t improve performance—it just increased cost and lead time.

See Precision Inserts vs Standard Inserts

for real-world examples of how surface finish affects mold behavior.

Repeatability is what separates a true precision insert from a standard one. It’s not enough that an insert fits once; it needs to return to the same position after disassembly, cleaning, or part replacement.

Connector molds and optical components are especially sensitive. A 0.01 mm shift in alignment can lead to defective products or increased flash. In my experience, checking repeatability before committing to a design saves hours in trial adjustments.

Sometimes, we even mark reference edges and do multiple assembly-disassembly cycles in the workshop to verify this. It’s tedious, but the cost of skipping it is higher in production.

For more on connector molds, see Precision Mold Components for Connector Molds

.

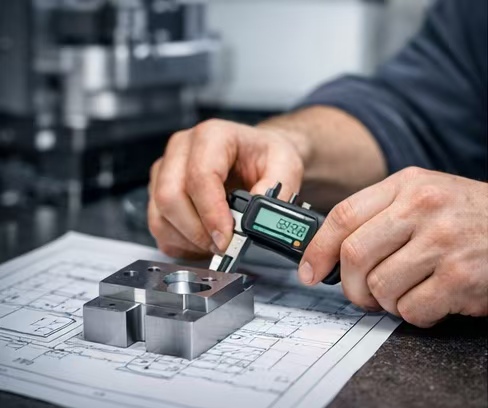

Drawings are the target, but machining makes it real. CNC machine stability, cutting parameters, tool wear, and thermal effects all play a role. Even a perfectly designed insert can be ruined if the process isn’t controlled.

Inspection is another critical point. Checking dimensions only at the end of production often misses drift during machining. We measure critical dimensions at multiple stages to catch issues early.

High precision machining isn’t about fancy machines alone—it’s about a repeatable, controlled process. We’ve found that process consistency is often more important than absolute tolerances.

Not every mold benefits from extreme precision. Using high precision inserts for simple plastic housings is overkill. It increases cost and lead time without improving production stability.

Precision inserts are necessary when:

Dimensional accuracy directly affects product quality

Multiple components must fit together perfectly

The mold will run for hundreds of thousands of cycles

In simpler molds, standard inserts with reasonable tolerances often perform fine. Choosing the right level of precision based on application, material, and production volume is the smarter approach.

High precision mold inserts aren’t defined by a single number or surface finish. They are the result of tolerance control, surface quality, fit, repeatability, and machining process working together.

From my perspective, the goal isn’t chasing the smallest tolerances. It’s about achieving consistent, predictable, and stable performance where it really matters—reducing trial adjustments, avoiding defects, and keeping molds running smoothly.

For further guidance, check High Precision Machining and Precision Mold Components to see how these principles apply across different molds.