Key Standards for LED Bracket Mold Processing - XP Mold Professional Solutions

With the development of the market and increasing demands, product requirements continue to rise. The number of mold component manufacturers and component varieties is also growing. Whether manufacturers can produce mold components that meet market needs is a challenge we must collectively address. So, what are the standard requirements for LED bracket mold processing?

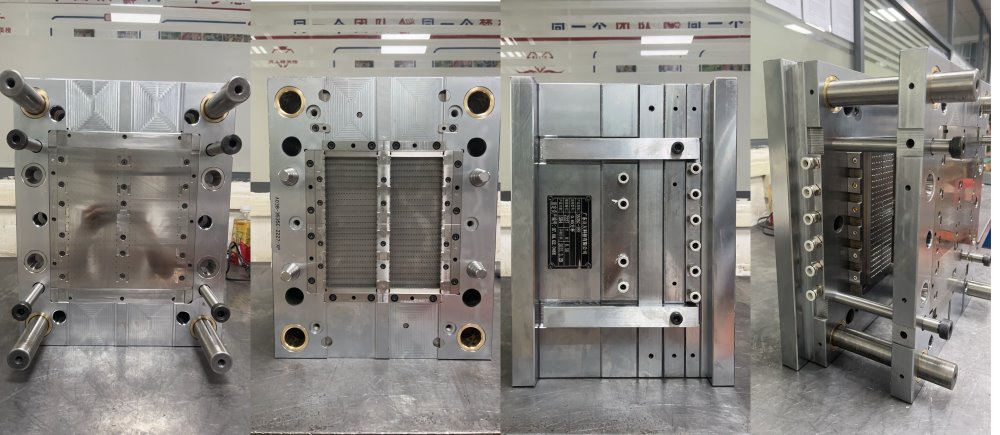

LED Lead Frame Mold

Thermal Fatigue Resistance

During operation, molds undergo repeated heating and cooling cycles, subjecting the cavity surface to tensile and compressive stresses. This can cause surface cracking and peeling, increasing friction, hindering plastic deformation, reducing dimensional accuracy, and ultimately leading to mold failure. Thermal fatigue is one of the primary failure modes for hot-work molds. Thus, such precision mold components must exhibit high thermal fatigue resistance.

Strength and Toughness

Precision mold components often operate under harsh conditions, with some enduring significant impact loads that may lead to brittle fracture. To prevent sudden breakage during operation, molds must possess high strength and toughness. The toughness primarily depends on the material's carbon content, grain size, and microstructure.

High-Temperature Performance

When molds operate at elevated temperatures, hardness and strength decrease, leading to premature wear or plastic deformation failure. Therefore, mold materials must demonstrate high tempering stability to ensure sufficient hardness and strength at working temperatures.

Corrosion Resistance

Certain molds, such as plastic molds, are exposed to chlorine- and fluorine-containing elements in plastics. When heated, these elements release highly corrosive gases (e.g., HCl, HF), which erode the mold cavity surface, increase roughness, and accelerate wear failure.

Fatigue Fracture Resistance

During operation, precision mold components are subjected to long-term cyclic stresses, often resulting in fatigue fractures. These fractures may manifest as low-energy multi-impact fatigue, tensile fatigue, contact fatigue, or bending fatigue. Fatigue resistance depends mainly on the material's strength, toughness, hardness, and inclusion content.

To meet these requirements, LED bracket mold processing must adhere to the following standards:

High Precision: Ensures dimensional accuracy and surface finish for high-quality LED brackets.

High Durability: Molds must withstand prolonged production runs without significant wear or damage.

Reliability: Consistent performance to guarantee uninterrupted production.

Adaptability: Ability to accommodate varying production conditions and material changes.

Cost-Effectiveness: Reasonable costs to ensure a strong return on investment.

As a professional mold manufacturer, XP Mold is committed to meeting these standards through advanced technology and stringent quality control. We continuously optimize design and manufacturing processes to enhance mold performance and longevity, addressing the evolving needs of the market and our clients.

XP Mold Advantages:

Material Expertise: Specialized alloys for enhanced thermal and mechanical properties

Precision Engineering: ±0.002mm tolerance guarantees

Quality Assurance: ISO 13485 & IATF 16949 certified processes

Proven Performance: Documented 40% lifespan improvement in client cases

Contact Us for Your LED Mold Solutions!