Precision Plastic Mold Manufacturing: Engineering Excellence for Modern Industry

Plastic molds are the backbone of countless industries, enabling the mass production of intricate and high-quality plastic components. As a precision mold manufacturing company, we specialize in designing and producing plastic molds that meet the exacting demands of industries such as automotive, electronics, medical devices, and consumer goods. This article explores the critical aspects of plastic mold manufacturing, emphasizing the technical expertise, advanced technologies, and meticulous processes that define our work.

The Role of Plastic Molds in Modern Manufacturing

Plastic molds are essential tools in injection molding, a process that transforms molten plastic into precise shapes and forms. The quality of the mold directly impacts the final product's accuracy, surface finish, and structural integrity. In industries where precision and consistency are paramount, such as medical devices or aerospace, even minor imperfections in the mold can lead to product failures or costly recalls. Therefore, the design and manufacturing of plastic molds require a combination of engineering precision, material science, and advanced manufacturing techniques.

Design: The Blueprint for Success

The design phase is the foundation of any successful plastic mold. Using advanced Computer-Aided Design (CAD) software, our engineers create detailed 3D models of the mold, incorporating all necessary features such as cavities, cores, cooling channels, and ejection systems. The design must account for factors like material shrinkage, flow behavior, and part geometry to ensure the mold produces components that meet exact specifications.

Simulation tools, such as Moldflow analysis, play a crucial role in optimizing the design. These tools allow us to predict how the molten plastic will flow through the mold, identify potential issues like air traps or weld lines, and optimize cooling channel placement to minimize cycle times. By addressing these challenges during the design phase, we reduce the risk of defects and ensure efficient production.

Material Selection: Balancing Performance and Durability

The choice of materials for plastic molds is critical to their performance and longevity. Common materials include pre-hardened steels, stainless steels, and aluminum alloys. Each material offers unique advantages:

Steel Molds: Known for their durability and wear resistance, steel molds are ideal for high-volume production. Grades such as P20 and H13 are widely used due to their excellent machinability and thermal stability.

Aluminum Molds: Lightweight and easy to machine, aluminum molds are cost-effective for low to medium-volume production. They also offer superior thermal conductivity, which can reduce cycle times.

Beryllium-Copper Alloys: These materials are often used in areas of the mold requiring high thermal conductivity, such as around cooling channels.

The selection of mold material depends on factors such as production volume, part complexity, and the type of plastic being molded. For example, abrasive plastics like glass-filled polymers require molds made from hardened steels to withstand wear.

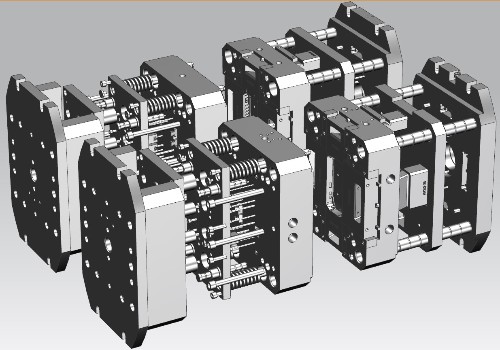

Precision Manufacturing: Turning Design into Reality

Once the design is finalized, the mold manufacturing process begins. CNC (Computer Numerical Control) machining is the cornerstone of modern mold production, offering unparalleled precision and repeatability. CNC machines are used to mill, drill, and grind mold components to exact specifications, ensuring tight tolerances and smooth surfaces.

For complex geometries or fine details, Electrical Discharge Machining (EDM) is employed. EDM uses electrical discharges to erode material, allowing for the creation of intricate shapes that would be difficult or impossible to achieve with traditional machining methods.

High-speed milling is another advanced technique used to produce molds with exceptional surface finishes and minimal post-processing. This method is particularly useful for molds requiring fine textures or polished surfaces.

Surface Treatment and Finishing

The surface finish of a plastic mold is critical to the quality of the final product. Various finishing techniques are employed to achieve the desired surface characteristics:

Polishing: This process creates a smooth, mirror-like surface that reduces friction and improves the flow of molten plastic. It is essential for molds used in the production of optical components or consumer goods with high aesthetic requirements.

Texturing: Surface texturing is used to impart specific patterns or finishes onto the mold, which are then transferred to the plastic part. This technique is commonly used in automotive interiors, electronics, and household appliances.

Coatings: Protective coatings, such as titanium nitride (TiN) or diamond-like carbon (DLC), are applied to enhance the mold's hardness, wear resistance, and corrosion resistance. These coatings extend the mold's lifespan and reduce maintenance costs.

Quality Control: Ensuring Perfection

Quality control is an integral part of the plastic mold manufacturing process. Every mold undergoes rigorous inspection and testing to ensure it meets the required specifications. Coordinate Measuring Machines (CMM) and optical measurement systems are used to verify dimensional accuracy, while hardness testers and surface roughness testers assess material properties and surface finish.

Trial runs are conducted to evaluate the mold's performance under real-world conditions. These tests help identify and address issues such as warping, shrinkage, or incomplete filling. By simulating the actual production environment, we ensure that the mold will perform reliably and consistently.

Innovation and Future Trends

The plastic mold industry is constantly evolving, driven by advancements in materials, technologies, and manufacturing processes. Additive manufacturing, or 3D printing, is emerging as a game-changer in mold production. It allows for the rapid prototyping of molds and the creation of complex cooling channels that improve efficiency and reduce cycle times.

Sustainability is another key trend shaping the industry. Manufacturers are increasingly adopting eco-friendly materials and processes to reduce their environmental impact. For example, biodegradable plastics and energy-efficient molding machines are becoming more prevalent.

Conclusion

Plastic mold manufacturing is a highly specialized field that combines engineering expertise, advanced technologies, and meticulous attention to detail. As a precision mold manufacturer, we are committed to delivering molds that meet the highest standards of quality and performance. By leveraging cutting-edge technologies and embracing innovation, we continue to push the boundaries of what is possible in plastic mold manufacturing.

In a world where precision and efficiency are paramount, plastic molds play a vital role in shaping the future of manufacturing. Whether it's producing life-saving medical devices or cutting-edge consumer electronics, XP Mold are designed to meet the diverse needs of our clients and contribute to the advancement of industries worldwide.