In the competitive world of precision mold manufacturing, innovation and expertise are critical to delivering high-quality solutions. As a leading precision mold company, we pride ourselves on pushing the boundaries of what’s possible. With cutting-edge technology and a commitment to excellence, we offer unparalleled capabilities that set us apart. Here’s why we should be your trusted partner:

1. Multi-Cavity Molds: Industry-Leading 5,760 Cavities

When it comes to high-volume production, efficiency and precision are paramount. Our ability to develop multi-cavity molds with up to 5,760 cavities per mold is unmatched in the industry. This capability allows us to meet the demands of large-scale production while maintaining exceptional accuracy and consistency. Whether you’re manufacturing small components for electronics or intricate parts for medical devices, our multi-cavity molds ensure maximum output without compromising quality.

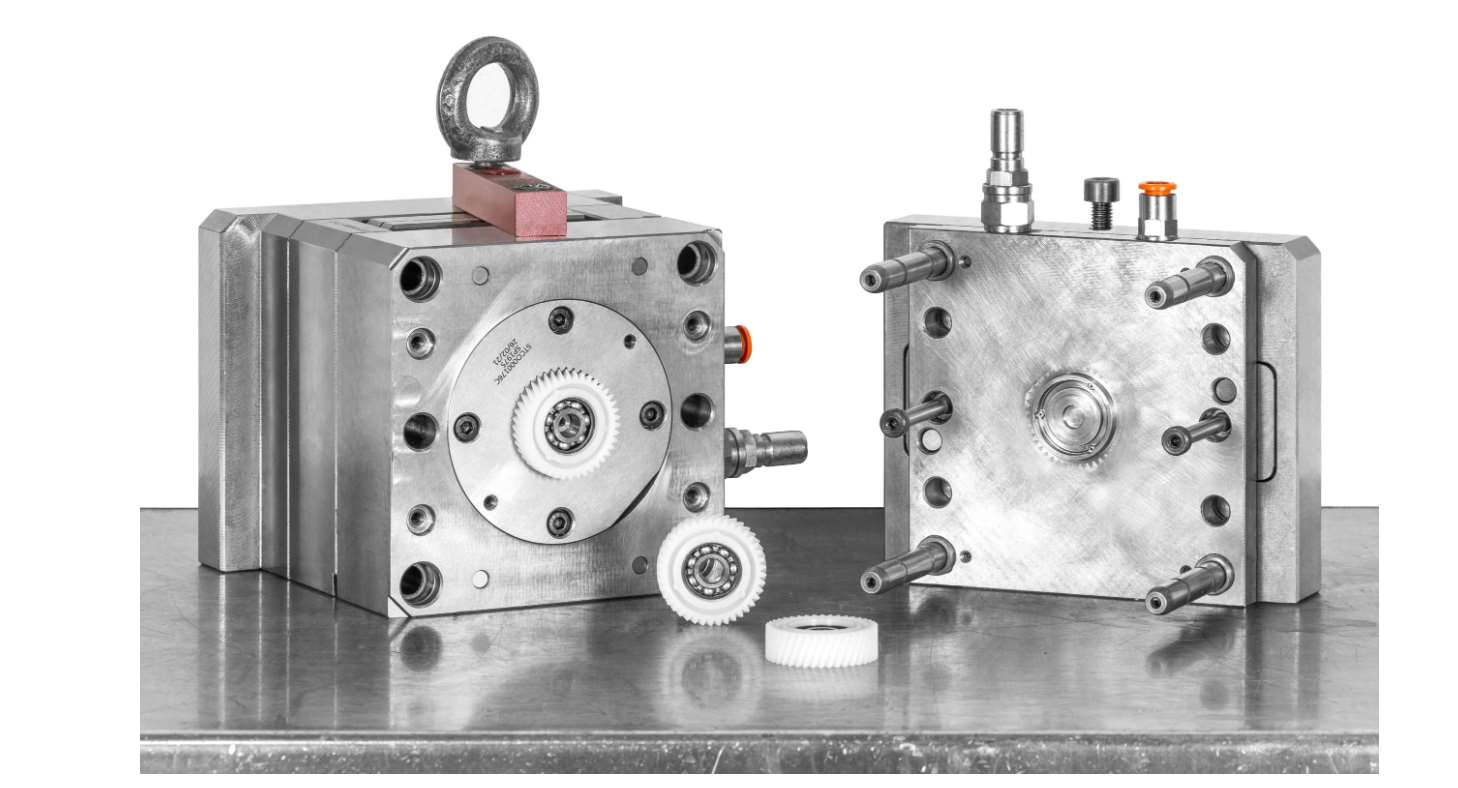

2. Metal-Insert Injection Molds: Complex Multi-Material Solutions

Combining metal and plastic components in a single mold requires advanced expertise, and we excel in this area. Our metal-insert injection molds enable the seamless integration of metal and plastic, creating durable, high-performance parts. This capability is ideal for industries such as automotive, aerospace, and electronics, where complex, multi-material components are essential. From intricate designs to demanding performance requirements, we deliver molds that meet the highest standards of precision and functionality.

3. Super-Mirror Surface Molds: Micro-Level Perfection

For applications requiring flawless surface finishes, our super-mirror surface molds deliver exceptional results. With surface finishes at the micrometer level, we ensure that your products meet the most stringent aesthetic and functional requirements. This capability is particularly valuable for industries like consumer electronics, medical devices, and luxury goods, where a perfect surface finish is critical. Whether you need molds for lenses, decorative components, or high-end products, our super-mirror molds set the standard for excellence.

4. Optical Threaded Molds: Precision at ±0.002mm

For ultra-precise threaded components, such as those used in optical devices or precision engineering, our optical threaded molds are second to none. With a thread pitch accuracy of ±0.002mm, we ensure that every thread is perfectly formed, meeting the exacting demands of industries where precision is non-negotiable. This capability is essential for producing components like lenses, connectors, and micro-mechanical parts, where even the slightest deviation can impact performance.

Why Partner with Us?

Unmatched Expertise: Our team of skilled engineers and technicians brings years of experience to every project.

Advanced Technology: We invest in state-of-the-art machinery and software to deliver molds with unparalleled precision.

Customized Solutions: We work closely with you to develop tailored solutions that meet your unique requirements.

Quality Assurance: Rigorous quality control processes ensure that every mold we deliver is flawless and ready for production.

Competitive Edge: Our advanced capabilities give you a significant advantage in your industry.

Conclusion

From 5,760-cavity molds to super-mirror finishes and ultra-precise threaded components, XP mold company is redefining industry standards. Whether you’re in automotive, electronics, medical devices, or consumer goods, we have the expertise and technology to meet your most demanding needs.

Why settle for less when you can work with the best? Let us help you bring your vision to life with molds that deliver unmatched precision and performance. Contact us today to discuss your next project!