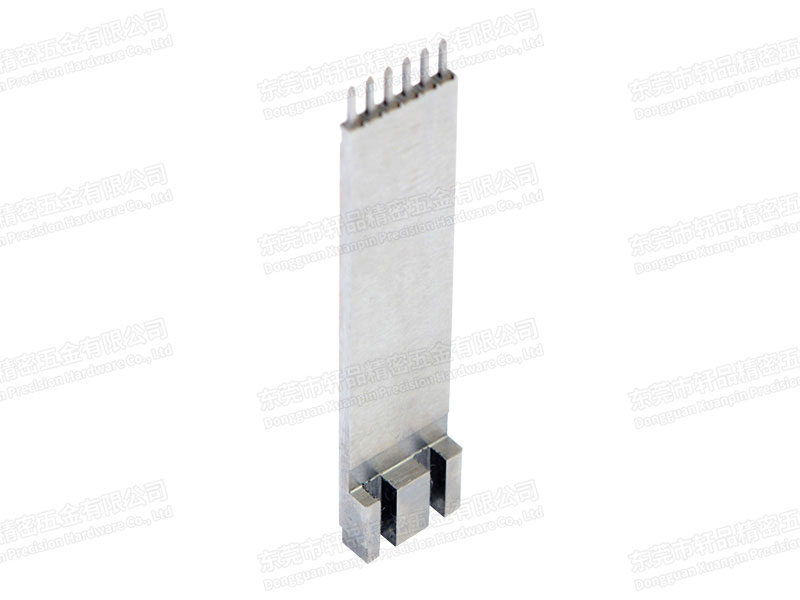

Professional mold inserts are an indispensable component of molds. During the mold making process, they help improve product quality, increase production efficiency, and increase mold output per unit time. To prevent high-quality mold components (such as mold inserts) from affecting mold performance, routine maintenance is essential, and relevant precautions should be known in advance.

Precision mold parts (mold inserts) are subject to inevitable bumps and bruises during use. Minor bumps should not be ignored and require regular, thorough inspections. Cracks and damage can affect their proper function and should be repaired promptly.

Mold inserts of XP Mold may sink after extended use. If this occurs, inspect the insert slots for foreign matter to determine the cause and remove any remaining debris promptly.

A major advantage of mold inserts is that they prevent mold damage. Lubricating frequently moving parts can prevent sticking and limit wear.

Mold inserts made during high-precision machining are lubricated during use. If oil residue remains in the gaps for a long time, it can affect their flexibility. Therefore, it is necessary to clean the oil with a specialized cleaner and air dry the inserts.

The above four points are crucial aspects of daily mold insert maintenance, ensuring proper mold operation and extending the lifespan of mold components. These maintenance tasks are simple, time-saving, and basic, and can be easily performed by most people.