Precision Injection Mold Components: The Unsung Heroes of Perfect Plastic Parts

Within injection molds, precision components function like "heart valves," directly determining mold lifespan, accuracy, and efficiency. Here are 8 critical precision components and their technical details:

I. Core Precision Components

1. Hot Runner System

Function: Precisely controls molten plastic flow, eliminating cold slugs

Key Parts:

Nozzle: Bore tolerance ±0.01mm, titanium alloy anti-corrosion

Heating Coils: PID temperature control (±1°C fluctuation)

Innovation: XP MOLD's multi-point temperature compensation

2. Guide System

Critical Components:

Guide Pins: Hardness HRC60+, straightness ≤0.005mm/m

Bushings: Oil-impregnated graphite self-lubrication

Standard: Japan JIS B5012 Ultra-Precision Grade

3. Ejection System

Precision Elements:

Ejector Pins: SKD61 steel, mirror polish (Ra≤0.1μm)

Return Pins: Preloaded spring anti-backlash design

4. Mold Inserts

Micron-Level Machining:

Carbide inserts withstand 5 million cycles

Nano-coatings (e.g., AlTiN) prevent sticking

5. Cooling System

Breakthroughs:

3D-printed conformal cooling (40% efficiency gain)

Copper alloy modules for medical molds

6. Venting System

Precision Design:

Multi-stage vents (0.02-0.05mm depth)

Sintered metal porous steels

7. Sensor Systems

Smart Monitoring:

In-mold pressure sensors (±0.5% accuracy)

Real-time IR temperature feedback

8. Quick Mold Change (QMC)

Precision Alignment:

Hydraulic clamping units (±0.005mm repeatability)

DIN 5480 spline interfaces

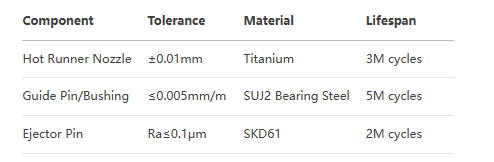

II. Technical Specifications Comparison

III. Industry Applications

Medical: Ceramic ejector pins for insulin pens (zero metal contamination)

Electronics: Tungsten carbide inserts for 0.2mm pitch connectors

Optics: Nano-polished cores achieve PV < λ/4

IV. Future Technologies

Smart Components: RFID-tagged ejectors with usage tracking

Self-Lubricating Materials: Graphene coatings (friction coefficient 0.05)

Atomic-Level Machining: Ion beam finishing for sub-nanometer roughness

Precision mold components are the "invisible champions" of injection molding, with their advancements driving industry progress. Through material innovation, ultra-precision machining, and smart monitoring, XP MOLD continuously redefines accuracy standards.